The Montevallo Times and Times Printing Co. operated from the Masonic Temple building on Main Street.

Times Printing started in the basement of the Masonic building but soon expanded to the street level floor to house its offices, bindery and, by the mid-1950's its offset pressroom. In the basement were located the composing room and Linotype machines as well as the letterpress pressroom. There was a dumbwaiter that ran between the two floors that allowed for easy transport of stacks of printing paper and completed jobs. The Times offices also served as a polling place during local elections.

When Times Printing Co. moved out of the Masonic building and into new quarters in the Whaley Shopping Center across the street, Zane Nathews located his men's shop in the storefront where the Times previously had its offices.

This is a view from the rear of the Masonic building in 1972.The windows on the top floor have long been blocked so that outsiders could not view the Masonic ceremonies that took place inside.

In recent years, attorney Mitchell Spears has had his offices in the same storefront as Times Printing and Zane's occupied in the past.

This is a shot of a basement door from 1972. Somehow, very large presses and other equipment had been moved through this narrow opening.

Behind these doors and windows was a hot, crowded, noisy, and dirty composing room and pressroom. The smell of ink and cleaning solution could be overwhelming.

Vedie Wyatt with her friend and loyal employee, Mrs. Montgomery, doing bindery work in the back room of the first floor. The windows are the same ones you can see in the photos of the rear of the building.

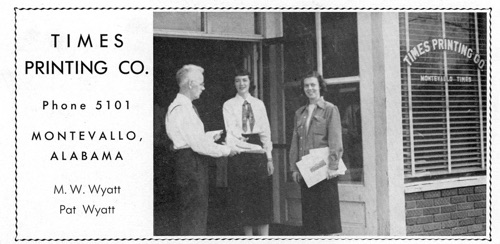

Times Printing participated in a job fair at Alabama College shortly after moving into the new plant in the Whaley Shopping Center. Mack Wyatt is in the center with two of his Times employees to his right and his daughter-in-law, Betty Wyatt, and his wife, Vedie to his left.

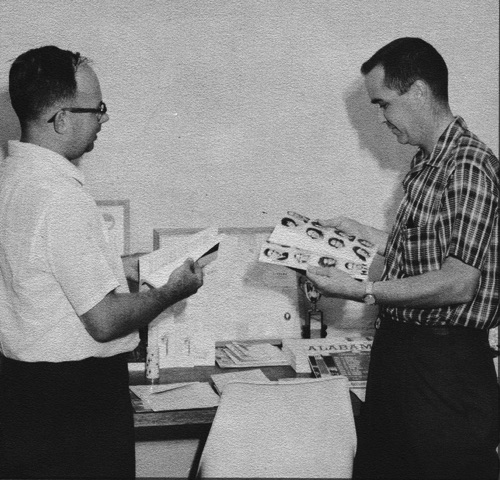

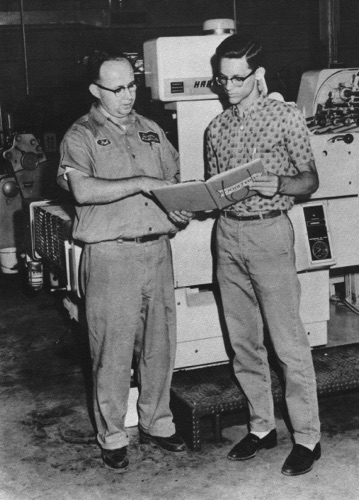

Pat Wyatt with Lee Barclay, Jr., editor of the 1961 edition of the Montevallo High School yearbook, Montala. Times printed the yearbook on the Harris offset press behind them.

Bobby Roman operates the Harris 20 x 26 inch single color offset press. The press was purchased new when Times Printing moved into the new plant in the basement of the Whaley Shopping Center and became the workhorse of the business.

A Chandler and Price platen letterpress that had been in the old shop in the Masonic building and then moved to the new plant in 1960.

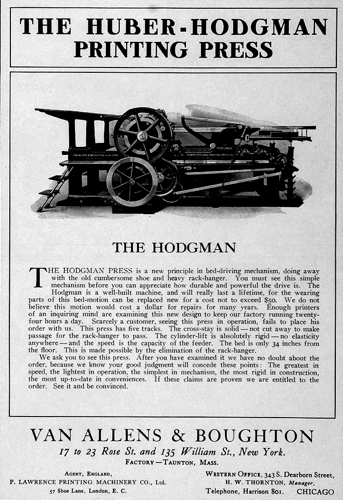

The big Huber single color hand-fed cylinder letterpress that was purchased in 1935, shortly after Mack Wyatt bought the Montevallo Times. This press was used for decades to print the newspaper and larger jobs, such as circus posters. Presses such as the Huber were the standard for small town newspapers for many years.

A Miehle cylinder letterpress very similar to Times' Huber being moved from Cather Publishing in Birmingham in 2014. It's new home is with a boutique printer in Montgomery where it is still in use today.

Pat Wyatt was always glad to accept discarded or obsolete printing machinery. Here he is moving a Linotype machine into the plant with the help of Mickey Henson, an unknown employee, and Pat's sons, Danny (seated) and Bobby.

This Linotype machine was still on the floor of Cather Publishing in Birmingham in 2014. It was no longer in use and was destined for a museum.

The composing room area of Times Printing in 1972. Type was still being set on Linotypes and this small press was used for pulling proofs from the hot metal lines of type.

This proof press was spotted at Cather Publishing in Birmingham in 2014 as they shut down their letterpress printing. Times had a similar proof press. The type was placed in the bed of the press, it was inked with a hand roller, a piece of proof paper was placed over the inked type and then the heavy cylinder was rolled by hand over the paper to make a printed impression into the paper.

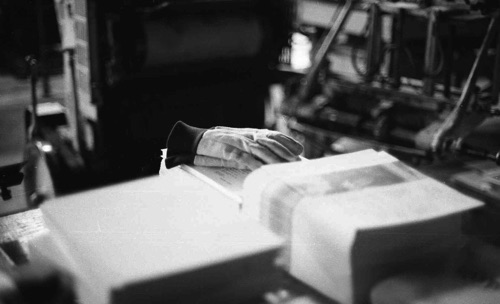

White cotton work gloves were used to load "lifts" of paper into the feeders of presses and other machines. The gloves prevented inky fingerprints from spoiling the paper and they helped prevent paper cuts.

Many cartons of paper stacked for a typical large printing job in the offset press area at Times Printing. A job this size would take several days to run.

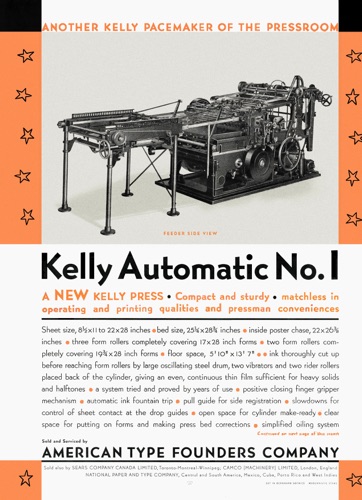

Letterpresses in the Times Printing pressroom, 1972. In the foreground is a Heidelberg "Windmill" press. It gets its name from the way the two feeder arms spin around like a windmill as sheets of paper are fed into the press and removed after printing into a delivery pile. This excellent German press was used for envelopes, business cards, letterheads, and form numbering jobs. In the background to the left is a Kelly Automatic cylinder letterpress. This press had been at the old shop in the Masonic building basement and had been used for fine quality book work. By 1972 it was used primarily for printing "reproduction proofs" for the offset department. To the right of the Kelly is the big Huber that also came from the old shop.

This photo was shot at Cather Publishing in Birmingham in 2014. This is the lead smelter and ingot pouring area. Next to the "pig" moulds is a machine that produced "spacing material" from a molten lead alloy. Times Printing had a similar set-up, although their smelter was a lot more primitive, using an open cauldron and ladle to melt and pour the lead pigs.

A "Ludlow" machine at Cather Publishing. Times Printing also had one of these line casting machines. They were used to cast individual slugs of large display type such as headlines in sizes larger than the Linotype could produce.

Following a fire that caused Times Printing to move out of the space under the Food Center in the Whaley Shopping Center, Pat Wyatt and his son Bobby built this new building almost single handedly in the 1980's. Following Pat's death in 1991, his wife Betty, and his two daughters continued to operate the business until they were forced to sell out a few years later. The business eventually folded and after more than 50 years was no more.

Click on the First Photo at right to start a slide show of photographs from Times Printing Co.

–––––––

Or click on the thumbnail for a larger individual view.